K&S’s rich heritage of tool and die manufacturing contributes to our ability to deliver quickly for our customers. From small, simple parts to very large complex 3D parts, we manufacture stamping tools that fit OEM needs.

K&S routinely manages large die programs with our complete in-house tryout capabilities. We have extensive experience working with many material types and are able to provide our customers with state-of-the-art design, die simulation and in-die sensing. From simulation through PPAP, K&S builds a wide variety of dies including: Transfer Line, Progressive, Deep Draw, Blank, Pierce and Cam. K&S can accommodate dies of all sizes due to our large bed machining and 40-ton lifting capability. We have the ability to manufacture a tooling package to fit your needs. Dies produced to life cycle demand with ongoing support ensuring up-time for your dies.

K&S also produces support tooling to better manage complete program demand:

- Welding Fixtures

- Assembly Fixtures

- Gauging

- Machining Fixtures

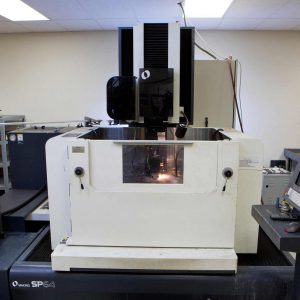

Our dedicated sensor lab equipment supports a wide range of die-sensing applications. All of our sensors and wires are buried in blocks and channels.